Aspartic Polyurea Products

Aspartic Polyurea Products for Water Parks and Swimming Pools

- Product Brief: Aspartate Polyurea (Referred to as Aspartic Polyurea)Known as the fourth-generation polyurea, aspartate polyurea overcomes the drawbacks of aromatic polyurea and aliphatic polyurea (the first, second and third-generation products). It boasts multiple advantages such as convenient and efficient const

Description

Aspartic Polyurea Roof Waterproof Coating

Aspartic polyurea roof waterproof coating boasts excellent waterproofing, heat insulation and weather resistance, while also delivering good decorative effects. It remains colorfast and crack-free after long-term outdoor exposure, eliminating concerns about roof waterproofing repair and maintenance.

Product Features

Superior Weather Resistance: Service life of over 20 years outdoors.

Seamless Integration: Combines waterproofing, anti-corrosion and decoration in one.

Safe, Eco-Friendly & Efficient: Environmentally friendly with convenient and efficient construction.

Scope of Application

Waterproof repair for small roofs and walls of various buildings; waterproof treatment for various finishing materials.

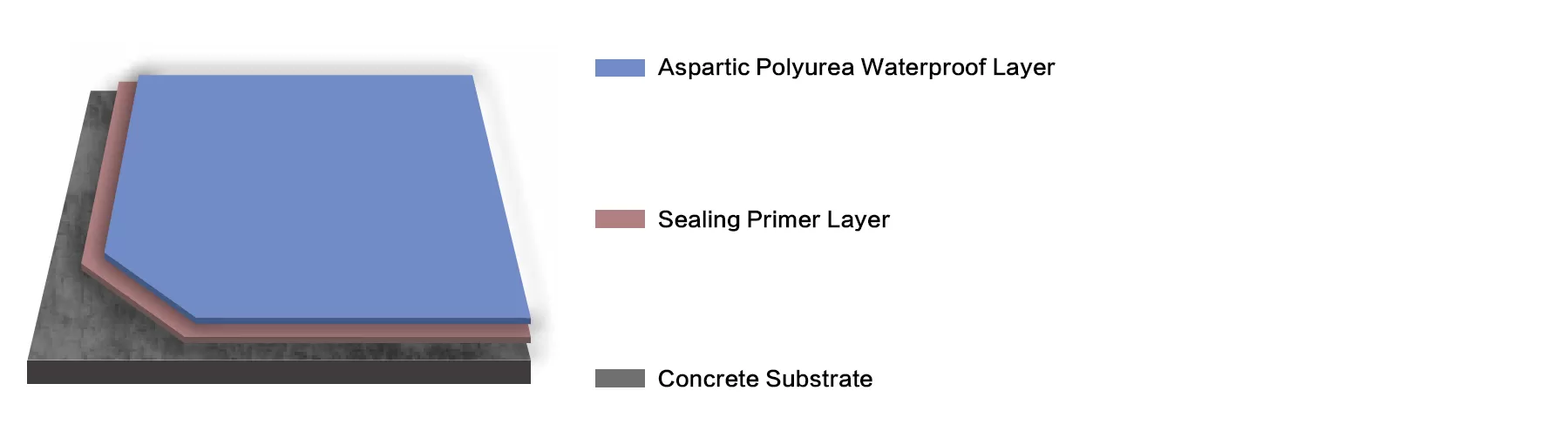

Product Structure

Technical Parameters

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Color | Gray/Blue/White | UV Resistance | No chalking, cracking or peeling after 1500h |

| Elongation | ≥350% | ||

| Adhesion | ≥4 MPa (on concrete substrate) | Solid Content (%) | 95±2% |

| Tensile Strength | ≥10 MPa | Pot Life | 0.4-1h (at 25°C) |

| Low-Temperature Flexibility | No cracking (at -35°C) | Surface Drying Time | 2-4h |

| Abrasion Resistance | ≥30 (750g/500r, mg) | Hard Drying Time | 10-12h |

| Hardness | ≥80A | Coating Interval | 10h-24h |

| Tear Strength | ≥40 N/mm | Mix Ratio | Main Agent:Curing Agent = 5:4 (by weight) |

Construction Process

Substrate Pre-treatment

Grind and clean the concrete substrate to remove dust; repair depressions and holes, and clear loose sand and other impurities.

Ensure the concrete substrate is dry (moisture content ≤5%) to meet construction requirements.

Primer Application

Roll-apply the sealing primer with uniform coverage.

Proceed to the next process only after the primer has dried for 6-8 hours (determined by touch—no stickiness).

Application of Aspartic Polyurea Elastic Waterproof Material

Apply the aspartic polyurea elastic waterproof material via rolling or troweling.

Control material dosage: 0.8kg/㎡ for a 0.6mm-thick coating.

Ensure uniform coating thickness, with no missed areas or sagging.

Notes

Material Usage Requirements

Mixing Ratio Control: Precisely weigh Components A and B of the aspartic polyurea roof waterproof coating according to the specified mass ratio to ensure accurate mixing.

Stirring Specifications: Thoroughly stir the mixed coating until homogeneous to prevent local sedimentation and ensure stable material performance.

Pot Life: The mixed material should have a pot life of at least 40 minutes. If the viscosity increases during construction, add 5%-10% of the special aspartic polyurea thinner.

Pre-Construction Conditions

Substrate Preparation: Before applying the primer, the substrate must be dry and dust-free to provide a sound foundation for subsequent construction.

Finished Product Curing Requirements

Curing Specifications: Prohibit personnel entry within 48 hours after construction; allow at least 7 days of curing until the coating is fully cured before putting it into use.

Transportation and Packaging

Avoid squeezing during packaging to keep the packaging intact.

Store the product in a cool, ventilated and dry place; the optimal storage temperature is 0°C-30°C.

Under normal transportation and storage conditions, the shelf life of unopened products is 1 year.

The product is packed in iron drums: 9kg/36kg per set.