Aspartic Polyurea Products

Aspartic Polyurea Roof Waterproof Coating

- Product Brief: Aspartic Polyurea Roof Waterproof CoatingAspartic polyurea roof waterproof coating boasts excellent waterproofing, heat insulation and weather resistance, while also delivering good decorative effects. It remains colorfast and crack-free after long-term outdoor exposure, eliminating concerns about r

Description

Aspartic Polyurea Roof Waterproof Coating

Aspartic polyurea roof waterproof coating boasts excellent waterproofing, heat insulation and weather resistance, while also delivering good decorative effects. It remains colorfast and crack-free after long-term outdoor exposure, eliminating concerns about roof waterproofing repair and maintenance.

Product Features

Superior Weather Resistance: Service life of over 20 years outdoors.

Seamless Integration: Combines waterproofing, anti-corrosion and decoration in one.

Safe, Eco-Friendly & Efficient: Environmentally friendly with convenient and efficient construction.

Scope of Application

Waterproof repair for small roofs and walls of various buildings; waterproof treatment for various finishing materials.

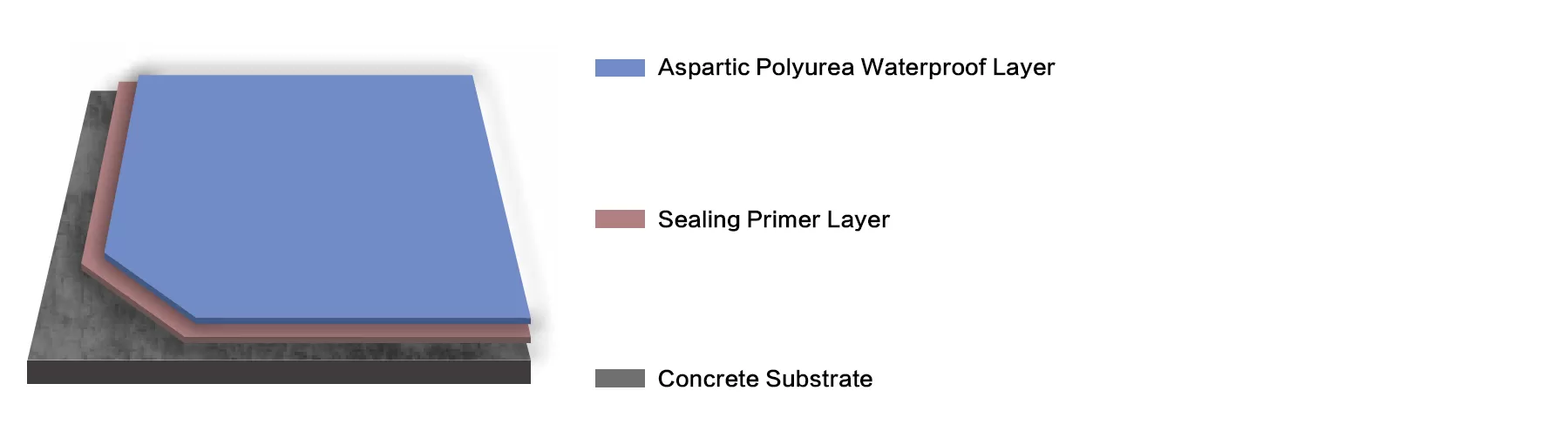

Product Structure

Technical Parameters

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Color | Gray/Blue/White | UV Resistance | No chalking, cracking or peeling after 1500h |

| Elongation | ≥350% | ||

| Adhesion | ≥4 MPa (on concrete substrate) | Solid Content (%) | 95±2% |

| Tensile Strength | ≥10 MPa | Pot Life | 0.4-1h (at 25°C) |

| Low-Temperature Flexibility | No cracking (at -35°C) | Surface Drying Time | 2-4h |

| Abrasion Resistance | ≥30 (750g/500r, mg) | Hard Drying Time | 10-12h |

| Hardness | ≥80A | Coating Interval | 10h-24h |

| Tear Strength | ≥40 N/mm | Mix Ratio | Main Agent:Curing Agent = 5:4 (by weight) |

Construction Process

Substrate Pre-treatment

Grind and clean the concrete substrate to remove dust; repair depressions and holes, and clear loose sand and other impurities.

Ensure the concrete substrate is dry (moisture content ≤5%) to meet construction requirements.

Primer Application

Roll-apply the sealing primer with uniform coverage.

Proceed to the next process only after the primer has dried for 6-8 hours (determined by touch—no stickiness).

Application of Aspartic Polyurea Elastic Waterproof Material

Apply the aspartic polyurea elastic waterproof material via rolling or troweling.

Control material dosage: 0.8kg/㎡ for a 0.6mm-thick coating.

Ensure uniform coating thickness, with no missed areas or sagging.

Notes

Material Usage Requirements

Mixing Ratio Control: Precisely weigh Components A and B of the aspartic polyurea roof waterproof coating according to the specified mass ratio to ensure accurate mixing.

Stirring Specifications: Thoroughly stir the mixed coating until homogeneous to prevent local sedimentation and ensure stable material performance.

Pot Life: The mixed material should have a pot life of at least 40 minutes. If the viscosity increases during construction, add 5%-10% of the special aspartic polyurea thinner.

Pre-Construction Conditions

Substrate Preparation: Before applying the primer, the substrate must be dry and dust-free to provide a sound foundation for subsequent construction.

Finished Product Curing Requirements

Curing Specifications: Prohibit personnel entry within 48 hours after construction; allow at least 7 days of curing until the coating is fully cured before putting it into use.

Transportation and Packaging

Avoid squeezing during packaging to keep the packaging intact.

Store the product in a cool, ventilated and dry place; the optimal storage temperature is 0°C-30°C.

Under normal transportation and storage conditions, the shelf life of unopened products is 1 year.

The product is packed in iron drums: 9kg/36kg per set.