Aspartic Polyurea Flooring

Aspartic polyurea flooring is a high-performance, multi-functional and eco-friendly flooring material. It offers a range of advantages including wear protection, waterproofing, corrosion resistance, environmental friendliness, and easy cleaning & maintenance. Additionally, it has excellent decorative properties—can be finished as chip flooring, colored artistic flooring, etc.—to meet personalized design needs. It is widely used in residential, commercial and industrial flooring applications.

Excellent Decorative Effect: Durable and colorfast over long-term use.

Slip & Wear Resistant: Provides reliable anti-slip performance and wear resistance.

Eco-friendly & Low-odor: Safe for use with no harmful emissions.

Suitable for residential garages, commercial spaces, office floors, etc. It is especially ideal for areas requiring high wear/scratch resistance, gloss/color retention, as well as outdoor locations exposed to direct sunlight.

| Parameter | Specification | Parameter | Specification |

|---|

| Adhesion | ≥2.5MPa (on concrete) | Pot Life | 0.3-1h (at 25°C) |

| Abrasion Resistance | ≤15 (750g/500r, mg) | Surface Drying Time | 4h |

| Hardness | ≥2H (pencil test) | Hard Drying Time | 10h |

| UV Resistance | No discoloration, blistering or peeling after 1500h | Coating Interval | 10-48h |

| Acid & Alkali Resistance | No discoloration, blistering or peeling after 240h | Application Method | Brushing, Rolling |

| Impact Resistance | ≥50kg·cm | Application Dosage | 0.15-0.25kg/㎡ |

| Gloss | Satin | | |

Substrate Pre-treatment: Clean the substrate to remove dust, ensuring it is clean, dry and free of oil stains or other impurities.

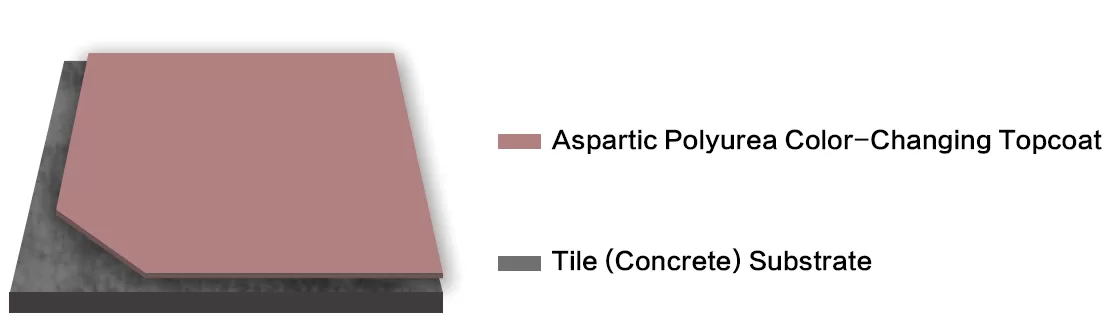

Topcoat Application: Apply the aspartic polyurea color-changing topcoat, controlling the dosage at 0.15-0.25kg/㎡ to ensure uniform coverage.

Drying & Use: Keep the area well-ventilated after construction; the flooring can be put into normal use once the topcoat is completely dry.

Material Usage: Precisely weigh Components A and B according to the specified mass ratio; stir thoroughly until homogeneous after mixing to avoid local sedimentation.

Pre-construction Requirement: The substrate must be dry and dust-free before applying the primer.

Finished Product Curing: Prohibit personnel entry within 12 hours after construction; allow at least 7 days of curing before putting the flooring into full use.

Packaging & Transportation: Avoid extrusion during packaging to keep it intact; prevent damage, sun exposure and severe jolting during transportation.

Storage Requirements: Store in a cool, ventilated and dry place; the optimal storage temperature is 0°C-30°C.

Shelf Life: Under normal transportation and storage conditions, the shelf life of unopened products is 1 year.